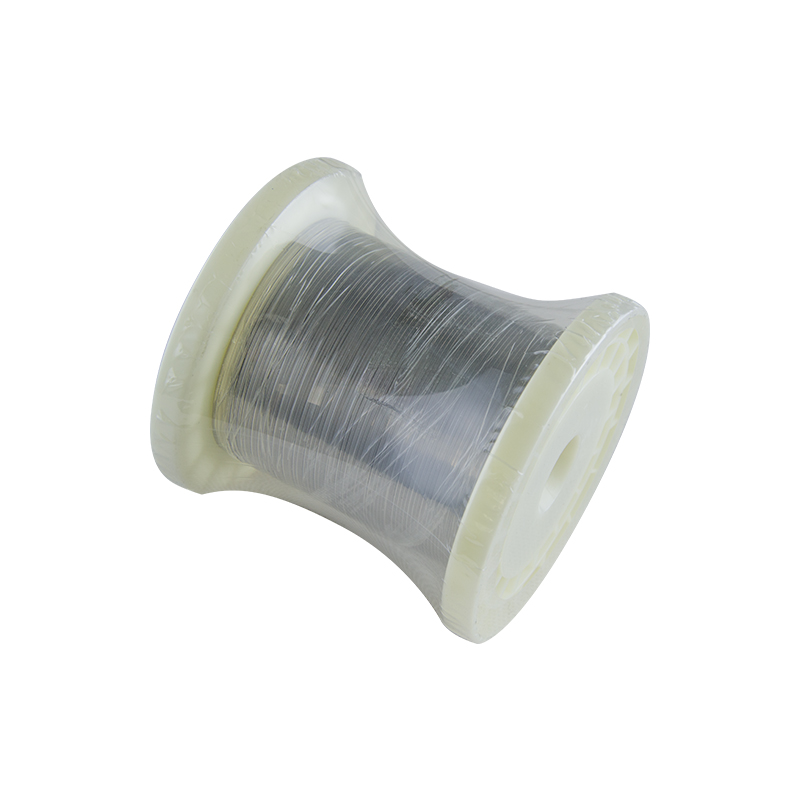

Sreang Téimh Friotaíochta Cóimhiotail FeCrAl 0cr23al5 le Teastas ISO9001

Sreang Téimh Friotaíochta 0cr23al5 le Teastas ISO9001

Sreang Friotaíochta déanta as cóimhiotail Nicil Cróim, cóimhiotail iarainn Nicil Cróim, cóimhiotail alúmanaim iarainn Cróim, cóimhiotail chopair nicil.

Úsáidtear go príomha i dtéitheoir, eilimint téimh agus friotóir, etc.

NiCr 80/20, NiCr 70/30, NiCr 60/15, NiCr 35/20

FeCrAl15-5, FeCrAl20-5, FeCrAl 25-5, srl…

Constantan, Cóimhiotal 30, Cóimhiotal 60, Cóimhiotal 90, etc.

Friotaíocht Leictreach ó 0.02 u ohm/m-1.53 u ohm/m

Oibrigh Teocht ó 200 C go 1400 C

Pls bíodh leisce ort teagmháil a dhéanamh linn má tá aon cheist ann.

NiCr:

Friotaíocht 20, Friotaíocht 30, Friotaíocht 40, Friotaíocht 60, Friotaíocht 70, Friotaíocht 80

FeCrAl:

FREASTAÍOCHT 125, FREASTAÍOCHT 135, FREASTAÍOCHT 140,

FREASTAIL 145, FREASTAIL 153

CuNi

Constantan, Cuprothal 5, Cuprothal 10, Cuprothal 15, Cuprothal 30, Eurica

| Grád Cóimhiotail FeCrAl | Comhdhéanamh Ceimiceach % | |||||||||

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | Re | Daoine eile |

| uasmhéid(≤) | ||||||||||

| 1Cr13Al4 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 12.5-15.0 | —- | 3.5-4.5 | 0.1 | Bal. |

| 0Cr15Al5 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 14.5-15.5 | —- | 4.5-5.3 | 0.1 | Bal. |

| 0Cr25Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 23.0-26.0 | ≤0.60 | 4.5-6.5 | 0.1 | Bal. |

| 0Cr23Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 20.5-23.5 | ≤0.60 | 4.2-5.3 | 0.1 | Bal. |

| 0Cr21Al6 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 19.0-22.0 | ≤0.60 | 5.0-7.0 | 0.1 | Bal. |

| 0Cr21Al4 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 21.0-23.0 | ≤0.60 | 3.0-5.2 | 0.1 | Bal. |

| 0Cr21Al6Nb | 0.05 | 0.025 | 0.025 | 0.7 | ≤0.60 | 21.0-23.0 | ≤0.60 | 5.0-7.0 | 0.1 | Bal. |

| 0Cr27Al7Mo2 | 0.05 | 0.025 | 0.025 | 0.7 | ≤0.40 | 26.5-27.8 | ≤0.60 | 6.0-7.0 | 0.1 | Bal. |

![]()

![]()

![]()

![]()

Comhdhéanamh Ceimiceach agus Airíonna:

| Airíonna/Grád | NiCr 80/20 | NiCr 70/30 | NiCr 60/15 | NiCr 35/20 | NiCr 30/20 | |

| Príomhcheimiceán Comhdhéanamh (%) | Ni | Bal. | Bal. | 55.0-61.0 | 34.0-37.0 | 30.0-34.0 |

| Cr | 20.0-23.0 | 28.0-31.0 | 15.0-18.0 | 18.0-21.0 | 18.0-21.0 | |

| Fe | ≤ 1.0 | ≤ 1.0 | Bal. | Bal. | Bal. | |

| Uasmhéid Oibre Teocht (ºC) | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Friotaíocht ag 20ºC (μ Ω · m) | 1.09 | 1.18 | 1.12 | 1.04 | 1.04 | |

| Dlús (g/cm3) | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Seoltacht Theirmeach (KJ/m·h·ºC) | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Comhéifeacht Teirmeach Leathnú (α × 10-6/ºC) | 18 | 17 | 17 | 19 | 19 | |

| Pointe Leá (ºC) | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Fadú (%) | > 20 | > 20 | > 20 | > 20 | > 20 | |

| Struchtúr Micreagrafach | austenít | austenít | austenít | austenít | austenít | |

| Maoin Mhaighnéadach | neamh-mhaighnéadach | neamh-mhaighnéadach | neamh-mhaighnéadach | neamh-mhaighnéadach | neamh-mhaighnéadach | |

![]()

![]()

![]()

![]()

| Grád Cóimhiotail CuNi | Friotaíocht leictreach (20 céim Ω mm² /m) | comhéifeacht teochta friotaíochta (10^6/céim) | Dlús g/mm² | Uasteocht (céim) | Pointe leá (céim) |

| CuNi1 | 0.03 | < 1000 | 8.9 | 200 | 1085 |

| CuNi2 | 0.05 | < 1200 | 8.9 | 200 | 1090 |

| CuNi6 | 0.10 | < 600 | 8.9 | 220 | 1095 |

| CuNi8 | 0.12 | < 570 | 8.9 | 250 | 1097 |

| CuNi10 | 0.15 | < 500 | 8.9 | 250 | 1100 |

| CuNi14 | 0.20 | < 380 | 8.9 | 300 | 1115 |

| CuNi19 | 0.25 | < 250 | 8.9 | 300 | 1135 |

| CuNi22 | 0.30 | < 160 | 8.9 | 300 | 1150 |

| CuNi30 | 0.35 | < 100 | 8.9 | 350 | 1170 |

| CuNi34 | 0.40 | -0 | 8.9 | 350 | 1180 |

| CuNi40 | 0.48 | ± 40 | 8.9 | 400 | 1280 |

| CuNi44 | 0.50 | < -6 | 8.9 | 400 | 1280 |

![]()

![]()

![]()

![]()

Catagóirí táirgí

-

Fón

-

Ríomhphost

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Barr